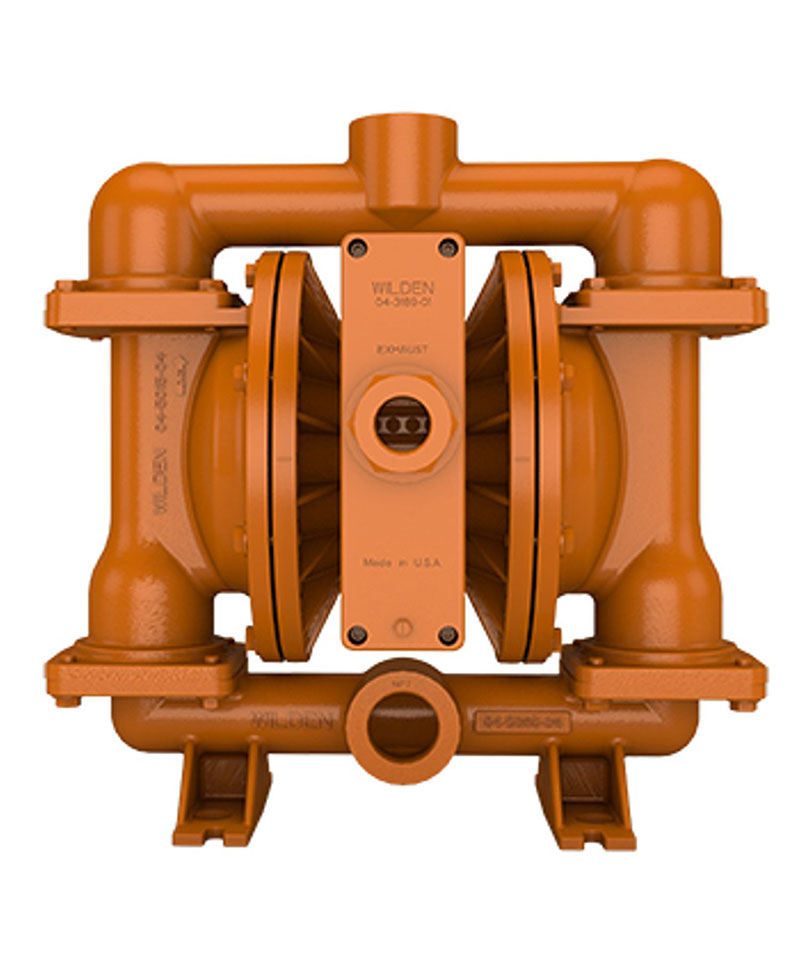

Features

FIT pumps are designed for superior containment, ease of maintenance, and are a direct replacement for existing threaded pumps in the field.

- 220 designates NPT or BSPT threaded inlet/discharge liquid connections

- Available with Pro-Flo X™ Air Distribution System

- Superior containment and direct replacement for existing bolted pumps

Contact your local authorized distributor today to purchase a PX220 pump!

Benefits and Features

The Successful Solution

- Bolted product containment for superior containment, sealability and ease of maintenance

- Intrinsically safe

- Variable flow and pressure

- Shear sensitive

- Dry-run capable

- Portable and submersible

- Viscous and non-viscous product transfer

- Large solids passage

- High suction lift

- Ease of operation and maintenance

Higher ROI

-

- Exact fit from bolt-down footprint to inlet/discharge connections to reduce installation costs and eliminate repiping expenses

- Fewer fasteners compared to other pumps with easy accessibility using power tools for faster maintenance and less

downtime

- Flexibility in aligning the wetted path assembly through lateral adjustment of the manifolds for easier installation into poorly piped systems

Dependable

- Longest Mean Time Between Repair (MTBR)

- Increased On/Off reliability

- Reduced turbulence

- Superior torque retention

- Anti-Freezing ADS

- Reduced internal friction

- Largest chemical compatibilities

Economical

- Greater flow per SCFM input

- Reduced air consumption and kilowatt usage

- Lower operational costs and downtime

- Optimized applications